An essential solution for producing fruit purees and nut pastes/butters, whether on an industrial scale or in smaller production setups. Its compact design makes it ideal for use in professional kitchens. The colloid mill is perfect for creating a variety of nut creams, pastes, and oils, such as peanut butter, cashew butter, hazelnut paste, pistachio paste, urbecha, tahini, and more.

This versatile machine allows you to grind and process a wide range of products, including almonds, peanuts, walnuts, hazelnuts, dry herbs and spices, cashews, coconuts, pistachios, sesame seeds, and other seeds.

Watch our amazing product video.

Advantages

- Capable of grinding raw materials into very fine colloidal size particles (more than gentle cosmetic creams)

- Modified volute-style outlet chamber for fast and efficient product discharge

- High rotor speed: 3000 rpm at 50 Hz allows for quick and highly efficient operation while maintaining chosen quality parameters

- Adjustable rotor-stator distance for precise grinding control – three-point chopping adjustment

- All components are made from food-grade stainless steel, ensuring long-lasting durability

- Compact design suitable for table installation or an optional independent support structure

- Safety grill at the product outlet ensures operator safety

- High-quality stainless steel conical hopper included in the standard package

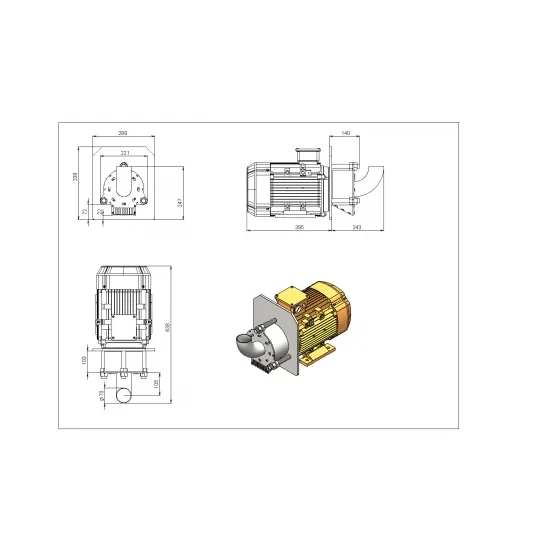

The basic version of colloid mill features a robust high-speed electric motor mounted on sturdy legs. Attached to the motor’s shaft is a specially designed rotor, while the stator, complete with a loading pipe, is securely mounted on the front panel. The innovative “snail” chamber and unloading pipe ensure smooth and efficient product flow.

What sets our new model apart is its adjustable rotor-stator distance, allowing you to achieve the perfect fraction size for your needs. The three-point adjustment system not only boosts processing efficiency but also broadens the range of raw materials you can work with.

The colloid mill operates on a principle of targeted mechanical impact, producing ultra-fine particles down to colloidal size (mere micrometers). This precision and versatility make it an indispensable tool for any production setting.

Processes

- grinding/dispersing

- mashing

- emulsification

- homogenization

Additional options

- support structure for the installation

- frequency converter for speed regulation as an independent control panel

- decorative casing made out of polished stainless steel

- height-adjustable legs (up to 100 mm)

Basic characteristics

- Capacity: 180-240 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia, EU

- Voltage: 380-400 V

Leaflets to download:

- SK: KOLOIDNÝ MLYN 132

- EN: COLLOID MILL 132

- RU: КОЛЛОИДНАЯ МЕЛЬНИЦА 132

- ES: MOLINO COLOIDAL 132

Do you have still question?

Send us a request at info@gastroprocessor.com