Fat melting unit for confectionery production

This specialized melting system is designed for processing solid fat blocks and is extensively used across the confectionery industry, from artisanal workshops to large-scale manufacturing facilities.

Electric tilting fat melter applications:

The unit is ideal for processing various fat-based products including:

- Animal fats

- Cocoa butter

- Margarine

- Food-grade waxes

- Dairy butter

- Chocolate glazes and coatings

The tilting container design ensures efficient melting and convenient product discharge, making it an essential tool for modern confectionery operations.

Advantages

- Space-saving design – compact stainless steel construction for durability and easy integration into any workspace

- High-efficiency heating – powerful 6500W electric heating element for fast, uniform melting

- Adjustable tilting system – 3-position tilt mechanism with secure locking for precise control during pouring

- Accurate temperature monitoring – built-in thermometer with bottom-mounted probe for real-time temperature tracking

- Customizable configuration – available with various optional accessories to meet specific production needs

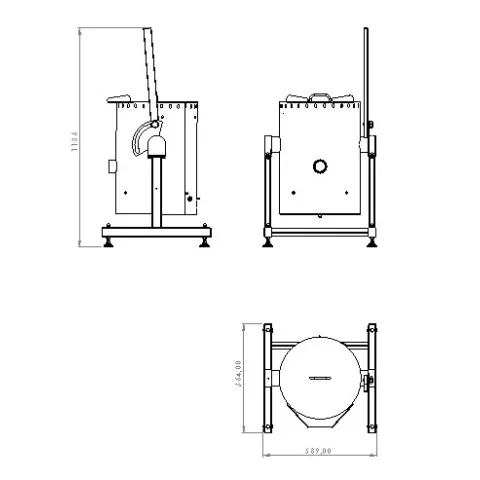

The basic version consists of an atmospheric working container with integrated electric bottom heating, installed on a free-standing stainless steel supporting structure, equipped with a thermometer, a tilt system for the working container, an upper lid and a 7-stage heating intensity regulator.

Options

- Height-adjustable legs

- Wheel support for easy transportation of the unit

- Stirring device

- Outlet valve

- Frequency converter in the form of an independent control panel with IP66 protection (when choosing the option in the form of a stirring device)

Basic characteristics

- Volume: 50l

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 220-230 V