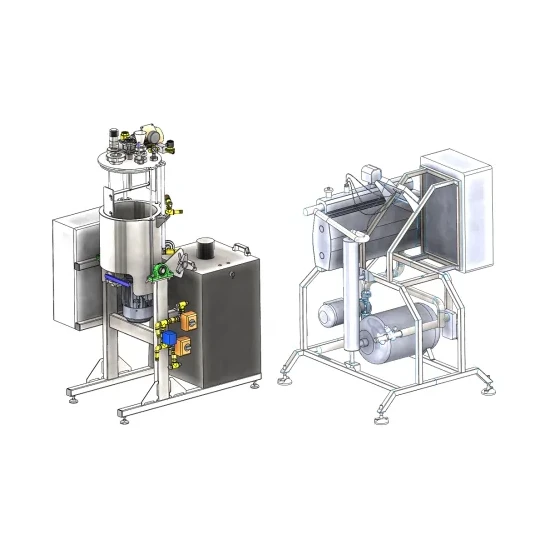

The vacuum homogenization unit is the ultimate solution for producing pilot batches and industrial-scale production of diverse products in smaller batches. Its versatility makes it perfect for start-ups, enabling the creation of pilot series, recipe development, and testing new products in laboratory settings. Whether you’re launching a new venture or innovating in an existing one, this unit offers unmatched flexibility and efficiency, making it the ideal choice for your production needs.

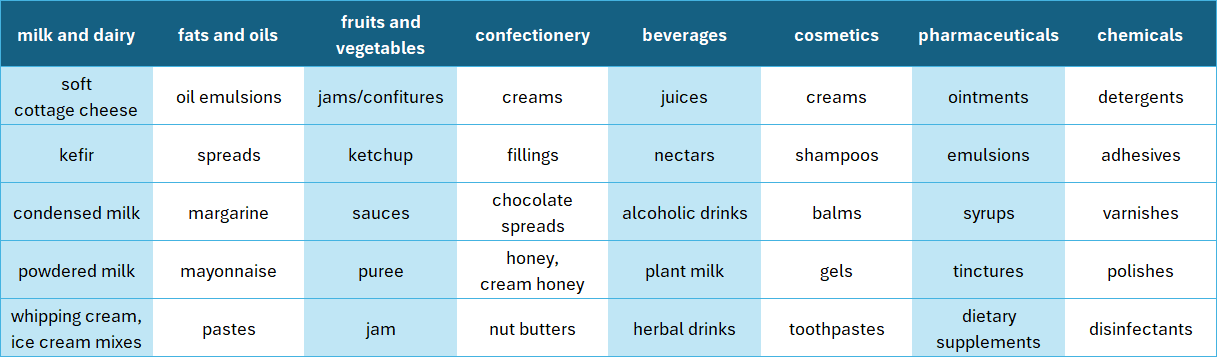

Unlock the potential of our vacuum homogenizer to produce a diverse array of food and cosmetic products. From milk and dairy, fats and oils, fruits and vegetables, confectionery, beverages, to cosmetics, pharmaceuticals, and chemicals, this versatile unit empowers you to create high-quality formulations across various industries.

Whether you’re in food production, cosmetics, pharmaceuticals, or chemical manufacturing, our vacuum homogenizer ensures precision and consistency in every batch, meeting your unique production needs with ease.

Advantages of our vacuum homogenizer

- Gas-Powered Lid Lifters: Included in the standard package for effortless operation.

- Triple-Layered Vessel: Features a stylish decorative body cover and effective thermal insulation.

- Thermal Coolant Duplicator: Ensures uniform cooling around the walls and bottom of the working tank, up to 0.5 Bar pressure.

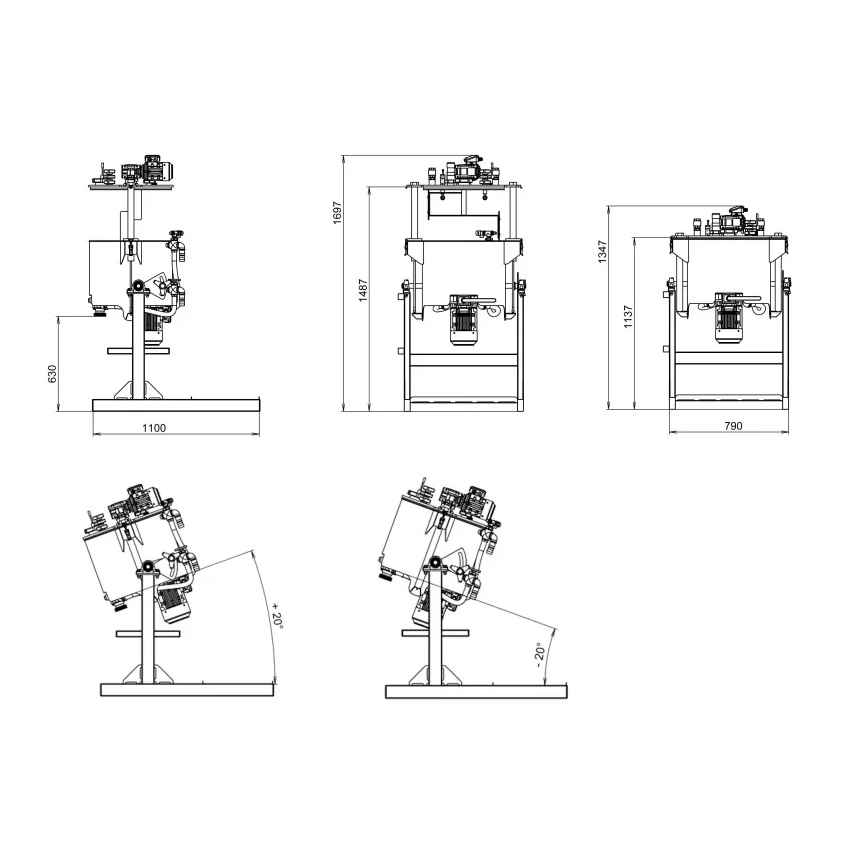

- Tilting Working Vessel: Allows tilting up to 20 degrees for quick and easy emptying of the processing chamber.

- No Dead Zones: Includes a bottom valve in the standard DN50 installation to prevent product buildup.

- Built-in Ultra Shear Bottom Homogenizer: Enhances product consistency and texture.

- Dry Running Capability: Allows the homogenizer to operate with minimal product volume, featuring two end seals with cooling.

- External Product Circulation: Option to connect to an external circulation loop for enhanced processing flexibility.

- Easy Disassembly: Facilitates quick dismantling and cleaning of the mixing device with scrapers.

- Food Grade Stainless Steel Construction: Available in AISI304 or AISI316 options for maximum durability and hygiene.

- Hygienic Compact Design: Simplifies cleaning and maintenance of the installation for efficient operation.

Experience the advanced features of our installation’s basic version, designed to optimize your production processes:

- Three-Layer Container: Crafted from food-grade AISI304 stainless steel, with a heating/cooling jacket for precise temperature control.

- Mechanical Tilting System: Allows for three working positions with secure fixation—ideal for unloading, active mixing, and service maintenance.

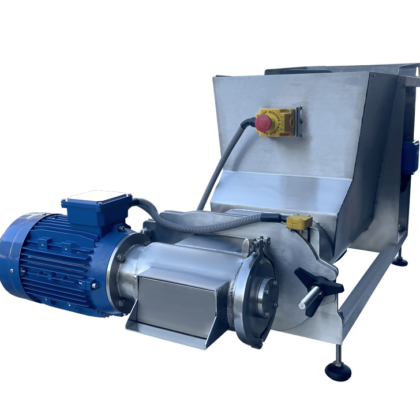

- High-Speed Ultra Shear Homogenizer: Positioned at the bottom, ensures intensive circulation and thorough homogenization of your products.

- Efficient Heat Distribution: Utilizes a thermal liquid circulating within the jacket to evenly distribute heat throughout the product.

- Dual Mechanical Shaft Seals: Equipped with an open cooling system for enhanced sealing performance and longevity.

- Electrically Driven Mixing Device: Facilitates thorough blending and consistency within the working container.

- Gas-Lifted Top Cover: Enhances accessibility with an auxiliary lifting system powered by gas lifts.

- Large DN50 Bottom Valve: Included for efficient release of the final product.

This robust configuration not only ensures superior performance but also simplifies maintenance and enhances operational efficiency, making it an indispensable asset for your production needs.

Processes

- Heating

- Cooling

- Dispersing

- Emulsification

- Deaeration

- Homogenization

- Mixing

- Mixing under vacuum

Vacuum Technology

Harness the power of vacuum to preserve the integrity of your products. By creating a vacuum within the working chamber, our system minimizes processing temperatures, safeguarding the vital active elements and properties of your materials. This process also reduces the risk of product contamination by eliminating air bubbles that may harbor trace elements.

Mixing and Stirring

Our equipment features a specially designed mixer and a container with a geometry that ensures thorough, uniform mixing without any dead zones. The innovative tilt functionality of the working container allows for gravity-assisted mixing, which is 30% more efficient than traditional methods, enhancing the performance of the bottom homogenizer.

Homogenization

Experience rapid and efficient dispersion, emulsification, and homogenization with our built-in rotor-stator homogenizer. Capable of handling particle sizes down to 5-10 microns, it produces products with a visually appealing appearance, stable structure, and extended shelf life. The homogenizer supports internal recirculation and product discharge, eliminating the need for additional pumps and enhancing hygiene and maintenance ease.

Heating and Cooling

A uniquely shaped jacket spans the entire height of the vessel, providing a substantial heat transfer area for efficient thermal management. It facilitates precise temperature control through external coolant circulation (not included in the standard package), ensuring optimal processing conditions for your applications.

Additional options

Customizable Automation and Vacuum Options

Tailored to meet diverse customer needs, our system offers various levels of automation, component loading methods, and a range of vacuum sources. Choose the configuration that best suits your production requirements.

Versatile Inspection Windows

Optimize visibility and operational control with inspection windows strategically positioned on the upper body of the DN65 unit. Options include:

- Inspection window with DN65 scraper for enhanced cleaning and maintenance.

- Inspection window with DN65 lighting for improved visibility in low-light conditions.

Precision Filling System

Ensure accurate ingredient dispensing with the filling cone equipped with a mechanical DN32 valve. This feature facilitates precise and efficient component loading.

Flexible Vacuum Generators

Select from multiple vacuum generation options to suit your specific application needs:

- Ejector-based vacuum generator powered by compressed air*.

- Water ring vacuum pump** for robust vacuum performance.

- Oil vacuum pump for reliable and efficient operation.

Advanced Control and Regulation

Enhance process control and efficiency with a vacuum retention and regulation system. This system ensures consistent vacuum levels critical for maintaining product quality.

Efficient Cooling and Heating

Achieve precise temperature control with integrated hot water (electric instantaneous heater) and ice water (chiller or refrigeration machine) sources. These coolant options support optimal processing conditions for both heating and cooling applications.

Intuitive Control Panel

Manage operations effortlessly with a user-friendly control panel mounted on the base. Featuring a comprehensive controller and recipe-saving capabilities, it streamlines workflow management and ensures consistent product quality.

* a source of compressed air is required – a 6-10 bar compressor (not included in the basic delivery package)

** water must be connected to cool the vacuum pump

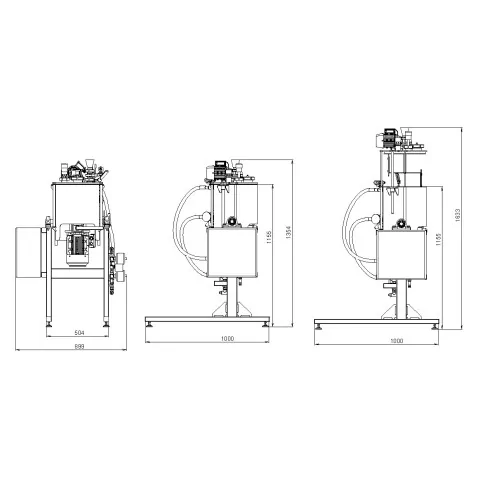

Basic characteristics

- Max vacuum: -0,8 Bar(-11.6 psi)

- Volume: 20 l / 50 l (5.3 / 3.2 gal.)

- Principle of operation: Batch mode

- Material: Stainless steel

- Country of origin: Slovakia

- Total power: 2,3 / 2,4 kW

- Voltage: 220 – 230 V

Do you still have a question?

If you’re aiming to produce wholesale soft cottage cheese, kefir, condensed milk, powdered milk, whipping cream or ice cream mixes, we have the right equipment for you.

Are you searching for a machine to create oil emulsions, spreads, margarine, mayonnaise, pastes, jams, ketchup, sauces, puree, or confitures?

Are you looking to optimize confectionery processes and seeking technology for creams, fillings, chocolate spreads, honey, cream honey, or nut butters? Or perhaps you need technology for preparing juices, nectars, alcoholic drinks, plant milk, herbal drinks?

If you’re starting a new venture in pharmacy, chemistry, or cosmetics, consider our vacuum homogenizer. It allows you to prepare creams, ointments, detergents, shampoos, emulsions, adhesives, balms, syrups, varnishes, gels, tinctures, polishes, toothpastes, dietary supplements, disinfectants, and more.

Send us a request at info@gastroprocessor.com, we will be happy to help you find the optimal solution for your production.